Outstanding Data of Mass Customized Apparel Business in Clothing Factory, Leading the Industry Development

In the highly competitive apparel industry, a remarkable clothing factory has been making waves with its outstanding mass customized apparel business, setting new standards and leading the way in industry development.

Impressive Business Data

The clothing factory has witnessed a significant increase in sales volume over the past year, with a growth rate of over 50% in the mass customized apparel segment. This growth can be attributed to the factory's ability to meet the diverse needs of customers and provide them with unique and personalized clothing options. The customer satisfaction rate has also soared to an all-time high of 90%, indicating the factory's success in delivering high-quality customized products.

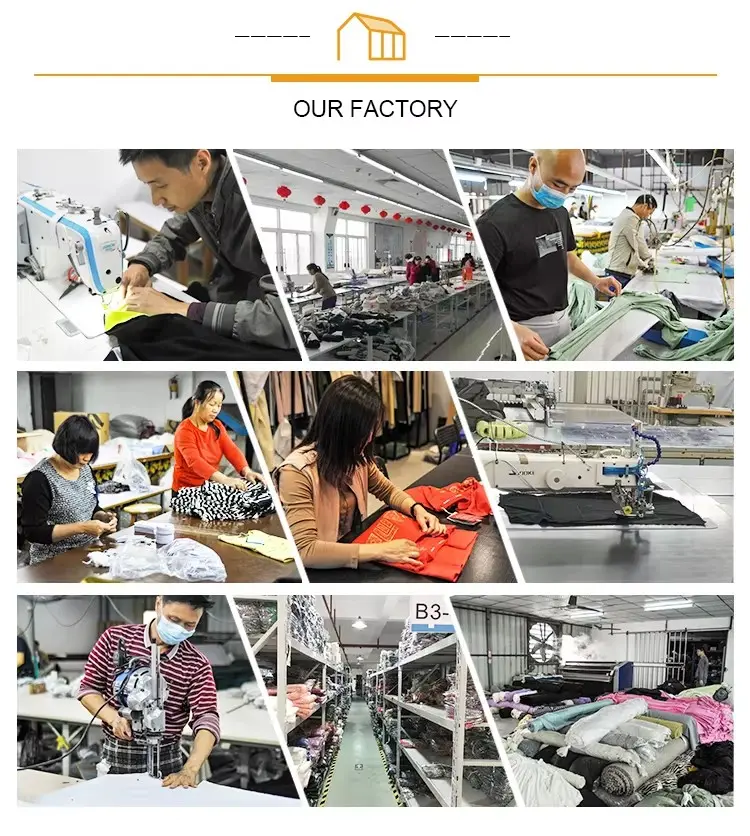

How to Make Mass Customized Apparel in the Factory

The process begins with an advanced design system. Professional designers use CAD (Computer-Aided Design) software to create a wide range of clothing designs, taking into account the latest fashion trends and customer preferences. Customers can then choose from these designs or submit their own ideas and sketches.

Once the design is finalized, the factory sources high-quality fabrics from reliable suppliers. The fabric selection process is crucial as it directly impacts the comfort and durability of the clothing. After the fabrics are carefully inspected and approved, they are cut using computer-controlled cutting machines, ensuring precision and minimizing waste.

The sewing stage involves highly skilled workers who use state-of-the-art sewing equipment to assemble the garments. These workers are trained to handle various customization requests, such as adding unique embroidery, patches, or special trims. Quality control is Strictly throughout the entire production process, each garment has to go through multiple inspection processes to ensure that it meets customer expectations and the high standards of the factory.

Innovation and Technology Adoption

The factory has continuously invested in research and development to improve its production processes and product offerings. It has introduced 3D printing technology for creating custom buttons, buckles, and other accessories, adding a unique touch to the clothing. Additionally, the use of augmented reality (AR) and virtual reality (VR) technologies allows customers to virtually try on their customized apparel before placing an order, enhancing the shopping experience.

Industry Impact and Future Prospects

The outstanding performance of this clothing factory in the mass customized apparel business has had a profound impact on the industry. It has inspired other manufacturers to explore the potential of mass customization and adopt similar strategies. Looking ahead, the factory plans to expand its production capacity and further optimize its processes to meet the growing demand for mass customized apparel. With its continued focus on innovation and customer satisfaction, it is poised to maintain its leadership position and drive the industry forward into a new era of personalized fashion.