New Trends in Global Garment Batch Customization – How Chinese Factories Empower B2B Clients with Flexible Production

1. Modular production system

Through the intelligent hanging production line and AI production scheduling system, the ability to process 30+ styles of mixed orders in a single day is realized. For example, an order of 200 basic T-shirts +300 POLO shirts +100 overalls can be completed in the same production line for cutting, process optimization and quality control, which is 50% more efficient than the traditional mode.

2. Full-link digital service

Customers can get real-time access through the independent station background:

• Online design tools generate 3D samples (support LOGO/ pattern/template customization)

• Intelligent quotation system (automatic calculation of fabric consumption, labor costs and logistics costs)

• Production progress board (accurate sewing, quality inspection, packaging node tracking to the hour level)

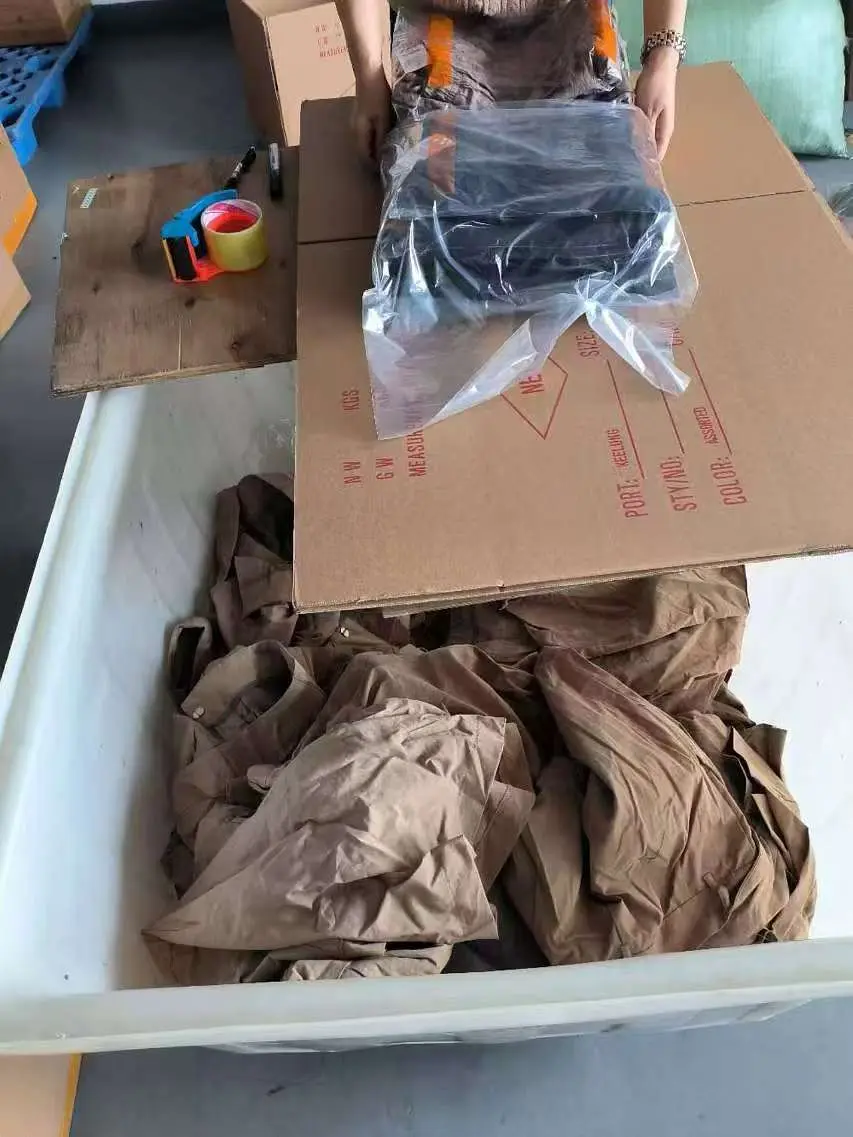

3. Small single fast counter-verification mechanism

For the trial order needs of customers in emerging markets, launched the "500 pieces MOQ +7 days delivery" fast service:

① Intelligent cutting machine automatically optimizes fabric utilization rate (save 8-15% consumables)

② Standardized process package covers 90% of conventional categories (reduce 30% communication cost)

③ Joint overseas warehouse to achieve the "production and delivery" model (South America/Middle East logistics time shortened by 40%)

Successful case

In Q4 2024, we completed 50,000 sunblock clothing customization projects for a German outdoor brand:

• Integrate mixed orders of 7 colors and 12 sizes

• Use laser cutting technology to achieve precision machining of special-shaped pockets

• Automatically sync Amazon inventory data through the stand-alone station API interface

Finally achieved the industry benchmark record from the order confirmation to the Port of Hamburg warehousing in only 9 days