From the cotton field to the closet: Revealing the birth of the custom-made shirt in the factory

Chapter One: The Awakening of Fiber - the raw Material Revolution

A shirt may begin in the cotton fields of Xinjiang or an organic farm in Brazil. The world's top shirt brands have begun to adopt "cotton blockchain traceability technology" : each cotton seed is implanted with a microchip, and the lighting and irrigation data during planting are uploaded to the cloud in real time. After the high pressure air flow cleaning in the cotton gin factory, the impurity rate is strictly controlled below 0.3%, and the final spun into 300 ultra-long cashmere cotton yarn, a single fiber can circle the earth's equator for three weeks without breaking.

At a research lab in Tokyo, bioengineers are extracting chitin from discarded crab shells to create smart fibers that automatically regulate body temperature. In Milan's dyeing workshop, nanoscale vegetable dyes use high-pressure infiltration technology to increase the color of fabrics by 40 percent, while reducing wastewater emissions by 90 percent.

Chapter 2: The Precision Dance of the digital Tailor

When fabrics arrive in smart clothing factories, AI design systems are revolutionizing. The designer enters the keyword "business leisure", the algorithm instantly generates 200 versions, and the 3D virtual fitting system optimizes the tailoring according to the global database of millions of body types. The cutting path of the laser cutting machine is optimized by the quantum computer, which can accurately cut 18 pieces in 1.2 seconds, and the fabric utilization rate is as high as 98.7%.

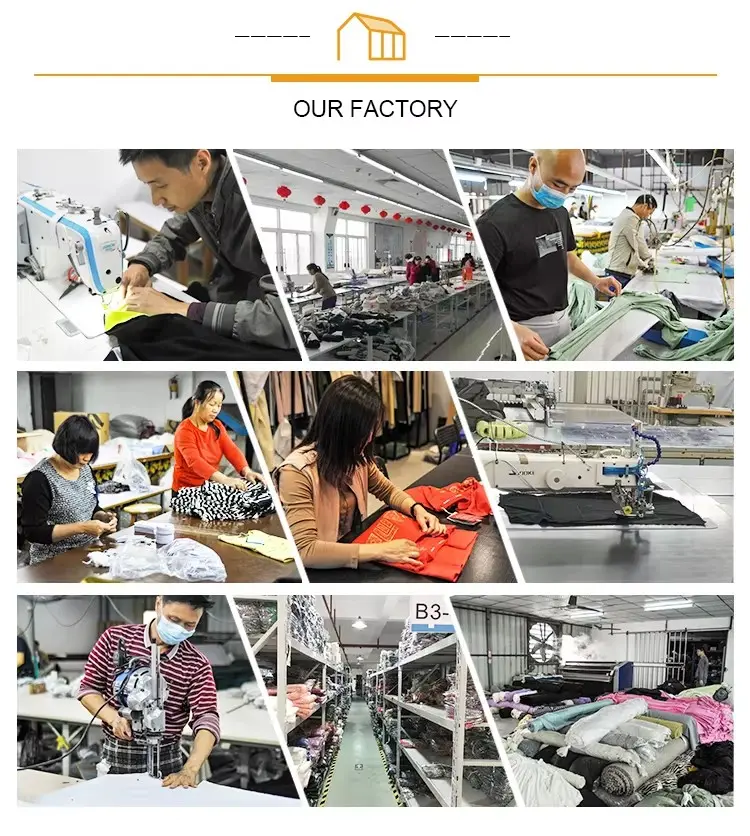

In the sewing workshop, the robot arm and the master carry out "man-machine collaboration" : the automatic sewing machine completes 12 hidden stitches in one minute, and the error is not more than 0.5 mm; The cufflink embroidery, which requires artistic judgment, is still done by hand by artisans with 20 years of experience, and the density of 22 stitches per inch is controlled by muscle memory.

Chapter Three: The Alchemy of Quality

In the TUV certified laboratory in Germany, the shirt needs to pass the rigorous "survival test" : after 50 consecutive industrial washing, the neckline deformation is less than 3%, the tearing strength must withstand 15 kilograms of tension, and even to simulate the polar climate test fabric elasticity. The infrared inspection system can capture 0.1 mm of wire, while the AI visual inspection compares 8,000 quality nodes per second.

A proper shirt also needs to undergo "human adjustment" : the anti-sweat strip on the inside of the neckline is simulated for skin PH, the underarm vents are bionic in honeycomb structure, and even the button stitching is hidden with anti-allergy coating. These invisible technologies make modern shirts last three times longer than they did 20 years ago.

Chapter 4: Global Collaborative Symphony

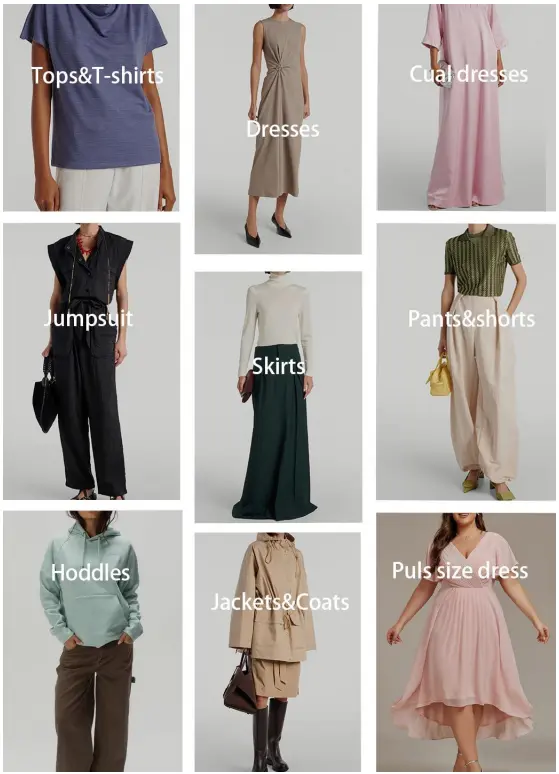

When you pick up a $199 shirt in a New York window, behind it is an industrial chain that spans 12 countries: creative drawings by Italian designers, optimized by an AI printing system in Vietnam, environmentally friendly dyes from Japan, buttons produced by precision machine tools in Switzerland, and finally flexible customization by a factory in China. A blockchain logistics system ensures that each shirt can be traced back to the farmer who grew the cotton, and a carbon footprint calculator shows the 42 percent reduction in carbon emissions during transportation in real time.

Data Insights:

- 380 shirts are produced every second worldwide

- High-end shirt making requires 87 hands of touch

- Smart manufacturing reduces the cycle time of custom shirts from 30 days to 6 hours

- The sustainable shirt market will exceed $82 billion by 2023

Conclusion:

When you put on this seemingly ordinary shirt, it already carries the gifts of agricultural civilization, the wisdom of the industrial revolution and the innovation of the digital age. From the first appearance of cotton bolls to the arrival of garments, this 120-day global journey has not only woven the epic of science and technology worn on the body, but also woven the unremitting pursuit of human beings for a better life. Next time you fix your collar, maybe you'll hear the words of civilization hidden in the stitching.

Extended reading:

Ready-to-wear Carbon Neutrality: Fashion's Technological Breakthrough

The 2048 Hours of a Shirt

Interactive map: Scan QR code to track your shirt's journey around the world

Note: The data in this article is from the International Textile Council 2023 Annual Report and the author's field research, and the character story has been authorized to use.